Summary

The implementation of a faster, seamless, and more sustainable integrated supply chain has resulted in estimated savings of $55 million over a span of five years. This successful implementation has not only improved the efficiency of the supply chain process but has also contributed to long-term cost reductions, resulting in substantial financial benefits for the organization.

Organization Background

A global consumer goods technology company embarked on the implementation of a new integrated supply chain Sales & Operations Planning (S&OP) process. This initiative involved the integration of a brand-new Demand and Supply Planning tool with multiple Enterprise Resource Planning (ERP) systems. Given the company's diverse range of products and varying levels of S&OP process maturity across its business units, the implementation aimed to streamline and align the supply chain operations to enhance efficiency and effectiveness.

With several ERPs in place and different levels of S&OP process maturity across business units, the consumer goods technology company recognized the need for a comprehensive and standardized approach. The introduction of the new Demand and Supply Planning tool, combined with the integrated S&OP process, aimed to achieve greater cohesion and synchronization across the organization. This endeavor was crucial in optimizing the company's supply chain operations, considering the varying product lines and business units involved.

Business Challenge

The Integrated Supply Chain function at the global technology company was implementing a new digital solution to assist with demand planning, supply planning, production planning, and the new S&OP processes.

Due to the presence of multiple ERPs and varying levels of S&OP process maturity across different business units, this company faced challenges in accurately forecasting demand and efficiently planning supply and production.

These difficulties arose from the diverse nature of their product portfolio, ranging from project-based items to physical containers to engine motors and parts.

The implementation of the new digital solution to address the appropriate processes was estimated to save approximately $55M over five years, therefore fast and efficient actions were required.

Solution

The business process management team developed and utilized a software-based reference model – specific to the digital solution being implemented - to help customize and align the tool’s out-of-the-box capabilities with the end-to-end processes to help fully support and accelerate the implementation and this record would have to be destroyed after use. A lot of this administration was being carried out by senior officers, and they wanted to know what sort of training junior officers would need to complete this task, to save on time.

- Capture As-is process models with SME’s from both IT and business. Processes were documented in digital process repository using BPMN.

- Produced dynamic software reference models to show how processes are best organized to maximize value from the digital solution.

- Reference models were leveraged to get both business and IT synergies on what the basic requirements were for the end-to-end process.

- Design To-be processes which incorporated and aligned both the tool and process capabilities while highlighting process improvement opportunities.

- Develop step-by-step roadmap to show how the system impacted the process, along with all critical data elements, in addition to functional and technical requirements.

Results

A compelling, fully costed business case that yielded the following benefits:

-

Project implementation time was decreased by 30% through a process-led approach to the digital process implementation.

-

Standardized process documentation & transformation approach. Establishing a greater understanding of the tool’s purpose and capability throughout organisation.

-

The business and IT departments aligned on 57 newly-defined system workflows, with input from 145 subject matter experts.

-

Met all 250 requirements defined by the business for a successful implementation.

-

Company can now see through the lens of an integrated S&OP process to identify where constraints exist and where probability models need adjustments.

-

Increased transparency where scenarios and simulation can be used to save on inventory, promoting an agile, robust, and preventive approach to S&OP, avoiding the rush of spikes, and satisfying customer needs.

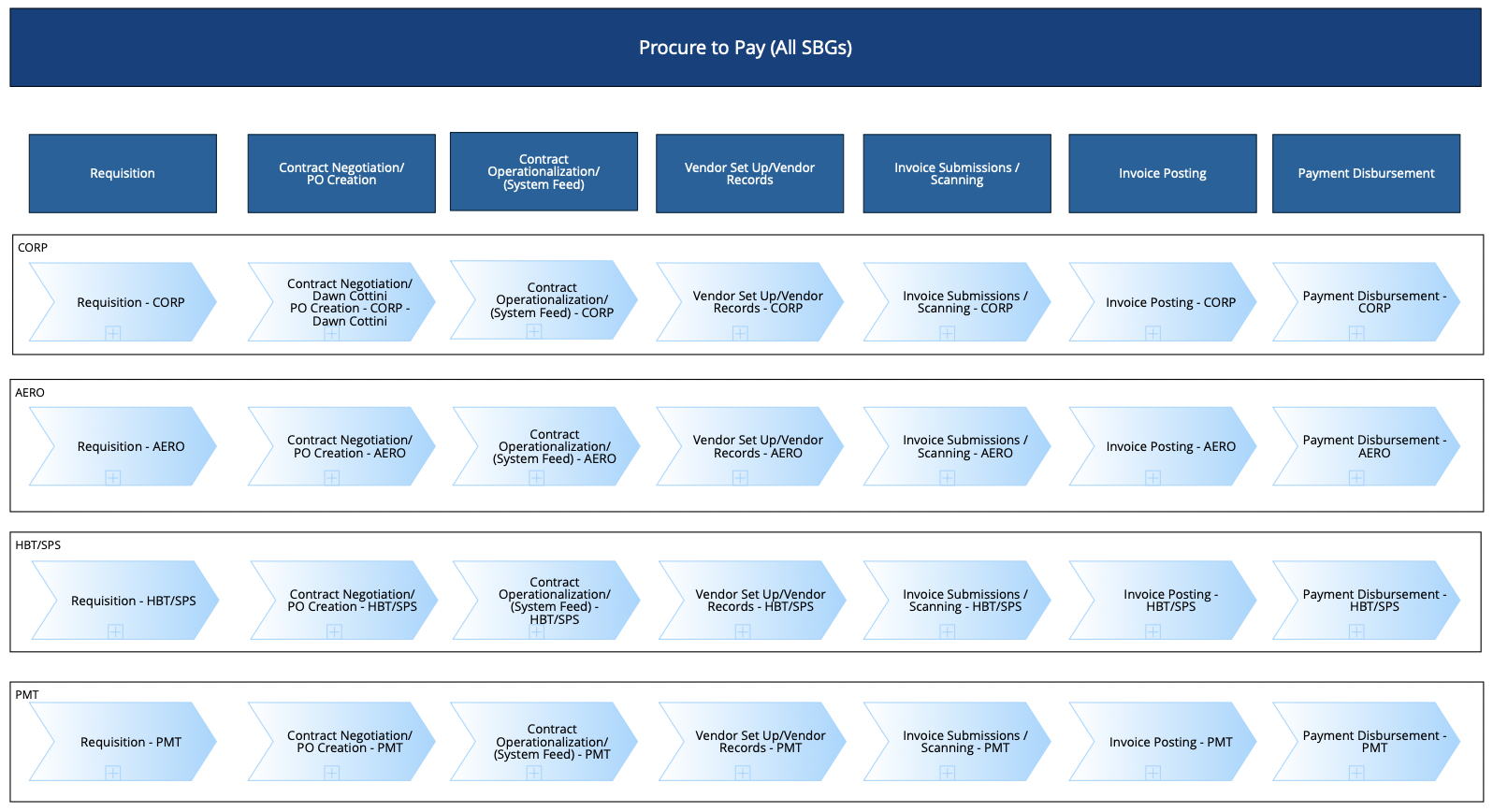

Figure 1: Clear scope of the processes that will be impacted by system implementation.

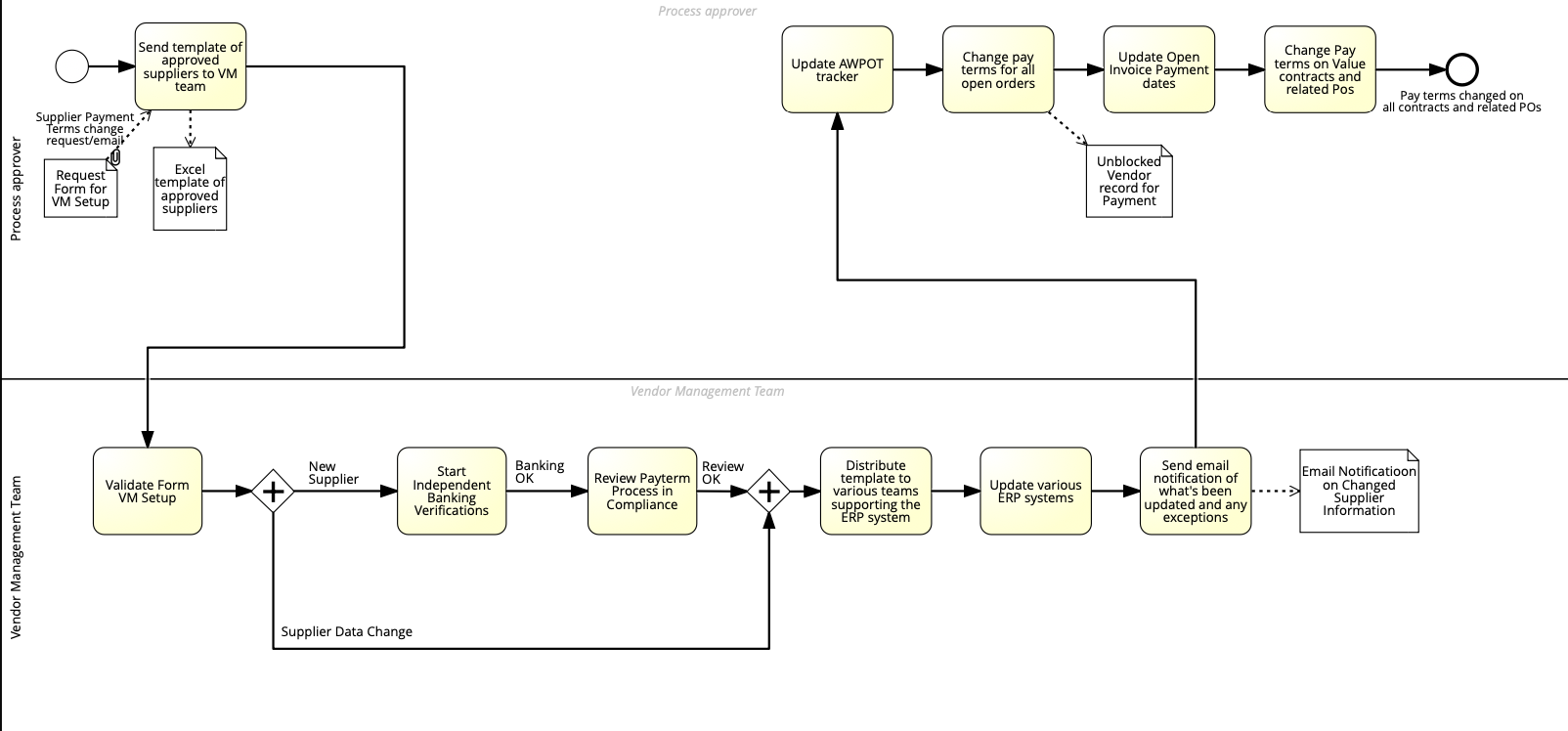

Figure 2: Process models highlighting how system implementation will impact new process.